Fault

1800 898 220

We have extensive information on our website and in our FAQs, but if you can't find what you're looking for feel free to contact us.

Renewable gas is a term used to describe gases that do not produce any additional carbon emissions in their production and use. Common forms of renewable gas include green hydrogen and biomethane. These can be used in the same way as natural gas is today.

Hydrogen does not contain any carbon and can be produced using water and renewable electricity, meaning the entire process is carbon free.

Biomethane is carbon neutral - it harnesses the energy potential from organic materials such as landfill gas, agricultural waste and sewage, supporting the circular economy.

By blending and ultimately replacing natural gas with renewable gas we can use our existing infrastructure to supply renewable gas to our customers. It also means customers retain their choice of energy supply, and those industries relying on gas can continue to access it.

Blended gas is the term used to describe gas supply that is part renewable gas and part natural gas. Blending renewable gas with the natural gas already being supplied to customers means we can start to decarbonise energy supply using our existing infrastructure and with minimal impact to customers. It also means customers retain their choice of energy supply, and those industries relying on gas can continue to access it.

Today Australia’s energy system relies on diverse sources of energy – natural gas and liquid fuels (petrol and diesel) are used for more than double the energy provided by electricity. It’s important that as we move towards net zero emissions we continue to use diverse sources of energy - if we don’t maintain diversity we risk developing a more costly and less reliable energy system overall.

Importantly, modelling indicates that decarbonising natural gas through renewable hydrogen can be up to 50% cheaper than electrification as it avoids significant investment in additional electricity infrastructure such as poles, wires and additional batteries.

It also means customers retain their choice of energy supply, and those industries relying on gas can continue to access it.

Australian Gas Networks (AGN) is one of Australia’s largest gas distribution companies with more than 25,000 kilometres of distribution networks and 1,000 kilometres of transmission pipelines.

Our networks serve more than 1.3 million homes and businesses in South Australia, Victoria, Queensland, New South Wales and the Northern Territory.

AGN receives a portion of the amount energy retailers charge their consumers for natural gas, which covers the costs of transporting natural gas from the high-pressure transmission pipelines to your street and home.

AGN is one of three companies that came together in 2017 to form Australian Gas Infrastructure Group (AGIG). AGIG is one of the largest energy infrastructure businesses in Australia, owning and operating infrastructure that delivers gas to more than two million Australian homes and businesses. AGIG also delivers gas that supports the Australian economy – for power generators, mines and manufactures.

AGN has a long history serving Australians. Our origins date back over 150 years to the gas distribution networks of the former South Australian and Brisbane Gas Companies, and the Gas and Fuel Corporation of Victoria.

We’re experts in building and operating gas pipelines to deliver gas safely and reliably to our customers. We call on this experience in the development of renewable gas projects.

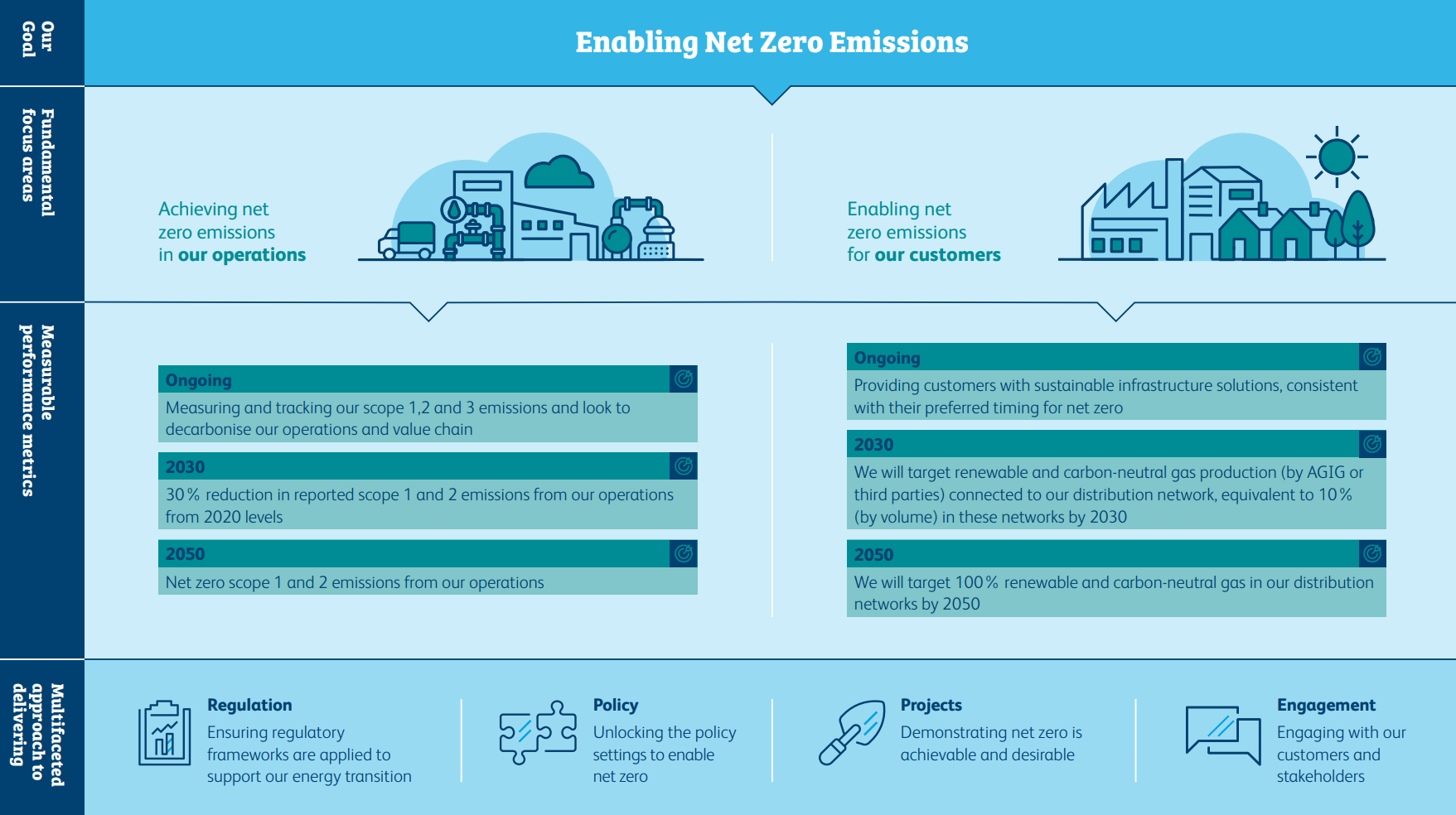

Our Net Zero Ambition is:

Whilst emissions from the use of gas delivered by AGIG infrastructure is not classified as scope 1, 2 or 3 emissions for AGIG, our Net Zero Ambition emphasises going beyond our direct responsibilities to support our customers in their efforts to reduce emissions.

We are targeting net zero scope 1 and 2 emissions across all our operations by 2050, with an interim aim to reduce our reported scope 1 and 2 emissions by 30% from 2020 levels by 2030.

That’s why we aim to facilitate customer access to renewable or carbon-neutral gases, at volumes equal to 10% of the gas delivered through the distribution network. Our aspiration is for 100% renewable or carbon-neutral gas in our distribution networks by 2050.

AGIG is already investing in projects that demonstrate the pathway to a low-carbon future. We are building renewable gas production facilities and preparing new and existing assets, for future fuel and carbon transport and storage.

Hydrogen is the simplest and most abundant molecule in the universe. It is colourless, odourless, non-toxic and an excellent carrier of energy.

Like natural gas, hydrogen can be used to heat buildings, power vehicles and produce electricity. Unlike natural gas, when burned, hydrogen produces only heat and water vapour - no carbon emissions.

In nature, hydrogen is found attached to other elements, which means we need to separate it before use. If we do this in a renewable way using wind and solar power the hydrogen is renewable hydrogen. Unlike natural gas, when burned, renewable hydrogen produces only heat and water vapour - no carbon emissions.

A common way of producing renewable hydrogen, and the way we are producing it, is through electrolysis with renewable electricity and water.

Electrolysis is the process of splitting water into hydrogen and oxygen using electricity. Electrolysis has been around for a long time, first appearing in the 1800s and is in use around the world today. By using renewable electricity, the entire process is carbon free – the hydrogen from this process is often referred to as ‘renewable’ or ‘green’ hydrogen.

Hydrogen can also be produced from natural gas or coal through steam methane reformation or autothermal reformation. This process releases CO2 and hydrogen produced this way is called ‘brown’ hydrogen. If the CO2 is captured and stored, then it becomes low carbon and is called ‘blue’ hydrogen.

We will use renewable electricity derived from the sun and wind in our projects to ensure that the entire process is carbon-free.

Renewable electricity may be supplied directly to the project (behind-the-meter) or can be sourced from the grid by purchasing and surrendering Renewable Energy Certificates.

Decarbonisation of energy is a big challenge, and we need lots of solutions. Renewable electricity is a very important part of the answer, but it can’t decarbonise all parts of the economy.

Using electricity to produce hydrogen is a complementary source of energy. It brings together gas and electricity networks, enabling renewable electricity to be used more efficiently – for example using excess renewable electricity (wind power that would have otherwise been curtailed at night or excess rooftop solar in the middle of the day) to produce hydrogen gas which is easily stored and can also be used to decarbonise the economy.

Hydrogen has long been used in Australia as a fuel for industry (such as steel making and fertilisers) and for oil refining. It can also be used in the manufacture of many common household goods, like margarine!

In recent years, using hydrogen as a direct energy source and as a transport fuel has gained momentum around the word, as we look to transition away from fossil fuels to carbon-free alternatives.

In late-2019, all Australian Governments agreed to sets a path to build Australia's hydrogen industry through the National Hydrogen Strategy. Under the leadership of Australia’s Chief Scientist, Dr Alan Finkel, the Strategy recognises hydrogen’s ability to decarbonise gas, power and transport and to underpin a new growth sector, with jobs and wider economic benefits.

It is timely for us to pursue hydrogen now, as the need to decarbonise grows and as the costs of technology (such as electrolysers) are reducing. There are multiple hydrogen projects online or under development across Australia, you can view a list of all Australian hydrogen projects at the ‘Australian Hydrogen Projects and Research Centres’ portal here.

Hydrogen as a clean energy source is already being used in Japan, South Korea, China, Europe, and the United States, both as 100% hydrogen and blended with natural gas. A few of these initiatives are outlined below:

You can be confident that your connection to the gas network will provide you with the energy you require and also help you transition to a low carbon future

Our current plans are to blend volumes of up to 10% renewable hydrogen by 2030. This blended gas remains consistent with the Australian Specifications for natural gas. Beyond 2030 we will look to convert to 100% renewable gas, which may require some change to appliances - work is already underway with the appliance sector to make this transition as smooth as possible.

We are committed to engaging with the community. When renewable gas projects are developed in your area we will let you know well in advance to ensure any questions you may have are answered.

We are experts in developing and operating gas infrastructure safely and reliably. Our commitment to safety underpins everything we do, and we must be satisfied that our renewable gas projects are safe before first production.

Hydrogen, like other fuels, is flammable and this is a key reason it can provide us with energy. It also means we need to treat hydrogen and blended gas with respect, as we do natural gas, electricity, petrol and other energy carriers.

The properties of hydrogen are well known and there is a significant body of evidence on its safe handing, including from industries that have produced, transported and used hydrogen for more than 100 years.

While hydrogen is odourless and burns with an invisible flame, odorants and colourants will be added for use in the home, such that flames can be seen and leaks can be detected by smell - just like natural gas. Our networks are also predominately polyethylene (plastic), which is suitable for 100% renewable gas.

As long-term owners of the gas networks, we are satisfied that we can adapt to the safety requirements for managing renewable gases. We are further subject to regulation by government bodies, which are designed to ensure our commitment to safety, reliability and service continue.

Yes. The areas to which we are supplying blended gas, as well as the majority of our networks across the country, are new generation polyethylene (plastic pipes) and are suitable for transporting hydrogen.

The introduction of hydrogen into our network does not cause our gas pipes to leak. On occasion gas pipes do leak for other reasons though, such as damage from tree roots or damage by someone hitting the main.

Should a leak occur in the project area, our response and safety procedures remain the same.

If you are looking for more information on the use of hydrogen gas in existing networks you might be interested in these reports:

Neither hydrogen nor natural gas smell in their normal state.

Natural gas supplied via the gas network contains a special odorant to give it its distinctive smell, so that leaks can be detected. Blending up to 10% hydrogen with natural gas will not bring the odorant outside of acceptable levels. If there is a leak, you will still detect the ‘natural gas’ smell.

If you smell natural gas, report the leak immediately by calling the 24-hour 1800 GAS LEAK (1800 427 532).

There are also other routine gas safety measures in place on the gas network, including regular leak detection surveys, which use specialist equipment. These surveys will continue in the project zone as is normal in the rest of the network.

The blended gas contains up to 10% renewable hydrogen which is not expected to change the colour of the flame.

Gas safety advice for customers remains the same during the project. The number you call during an emergency remains the same at 1800 GAS LEAK (1800 427 532).

Historically, Australians relied upon Towns Gas to meet demand. Towns Gas was manufactured from coal and consisted of 50-60% hydrogen. Some places such as Hong Kong and Singapore still rely on Towns Gas.

Australia switched from Towns Gas upon the discovery of natural gas, because natural gas was considered more reliable and economic. This occurred in the 1970s in South Australia, whilst some places, including parts of Queensland relied on Towns Gas until the late 1990s.

Today we know that cost of producing hydrogen is decreasing and that blending renewable hydrogen with natural gas is the first step towards lowering carbon emissions.

Of course. On average there are approximately 100,000 new gas connections across Australia every year. Connecting to the gas network today provides you the benefits of natural gas – safe, reliable, controllable energy – and a pathway to renewable gas in the near future. The connection process will be no different for natural gas or a blended gas.

The appliances sold in Australia are designed to operate efficiently and effectively with natural gas. They are tested with varying gas compositions to account for the varying sources of natural gas supplied around Australia. One such “limit” gas contains 13% hydrogen, and therefore all certified household gas appliances sold in Australia have undergone a range of safety tests with this level of hydrogen.

Consistent with this and with our own appliance testing program, we are confident that your existing home appliances will work safely, reliably and effectively with up to 10% hydrogen blends and potentially even higher - with international projects supplying up to 20% hydrogen blends.

When receiving 100% renewable hydrogen gas – which is being targeted for post-2030 – new appliances or burner parts may be required.

100% hydrogen appliances are in use throughout Australia and the world today – we have hydrogen barbeques that we use at community events – but at the moment they are niche product whilst the market establishes itself. Appliance manufacturers are already working on hydrogen ready appliances that will easily transition from natural gas to hydrogen gas. Hydrogen cars, trucks and forklifts are also available.

Our Low Carbon Strategy outlines our plans to supply 10% renewable gas by 2030 before starting the conversion to 100% renewable gas. The timing of 100% conversion (post-2030) is aligned with when many appliances will be able to be replaced as part of their natural retirement cycle which will also contribute to a smooth transition.

Need to get in touch? You can contact us to find out more about our projects or register for updates using the below details.

1300 001 001 and press option 8

Register here to receive our e-news updating on project progress and our renewable gas journey